Company History

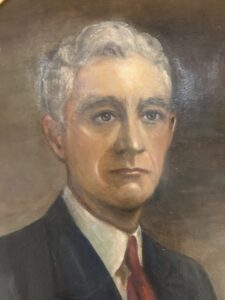

The Freeman Corporation is a family-owned wood veneer manufacturer based in Winchester, KY. Founded in 1914 by George E. Tomlinson and originally named The Tomlinson Company, The Freeman Corporation began as a manufacturer of hardwood lumber, tobacco hogsheads (storage barrels), and Tomlinson takedown tables, the first banquet tables capable of being instantly disassembled for storage. The sawmill steadily expanded and became a leading walnut lumber manufacturer. Following Mr. Tomlinson’s death in 1953, Gene Freeman, Mr. Tomlinson’s grandson, took over the company and installed the first veneer slicer in 1968.

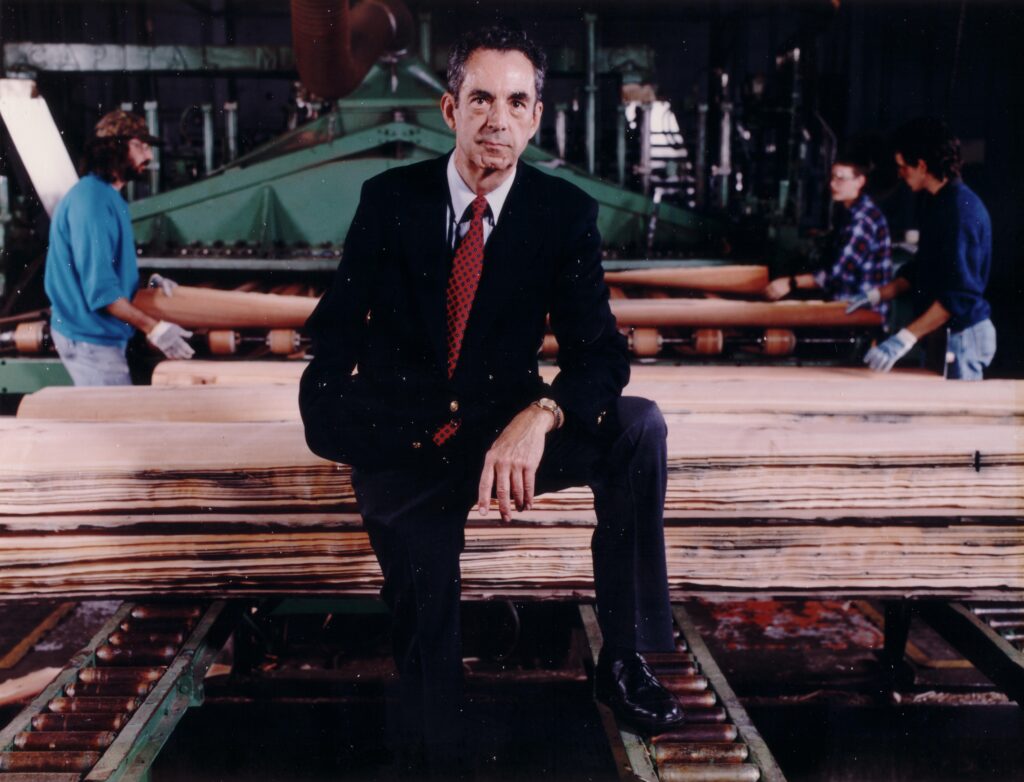

In 1982, Gene’s two sons, Reid and George, joined the business and learned the business from their father until Gene retired in 1991. The Freeman brothers have dramatically expanded the manufacturing operation and have built one of the largest wood veneer manufacturing companies in North America.

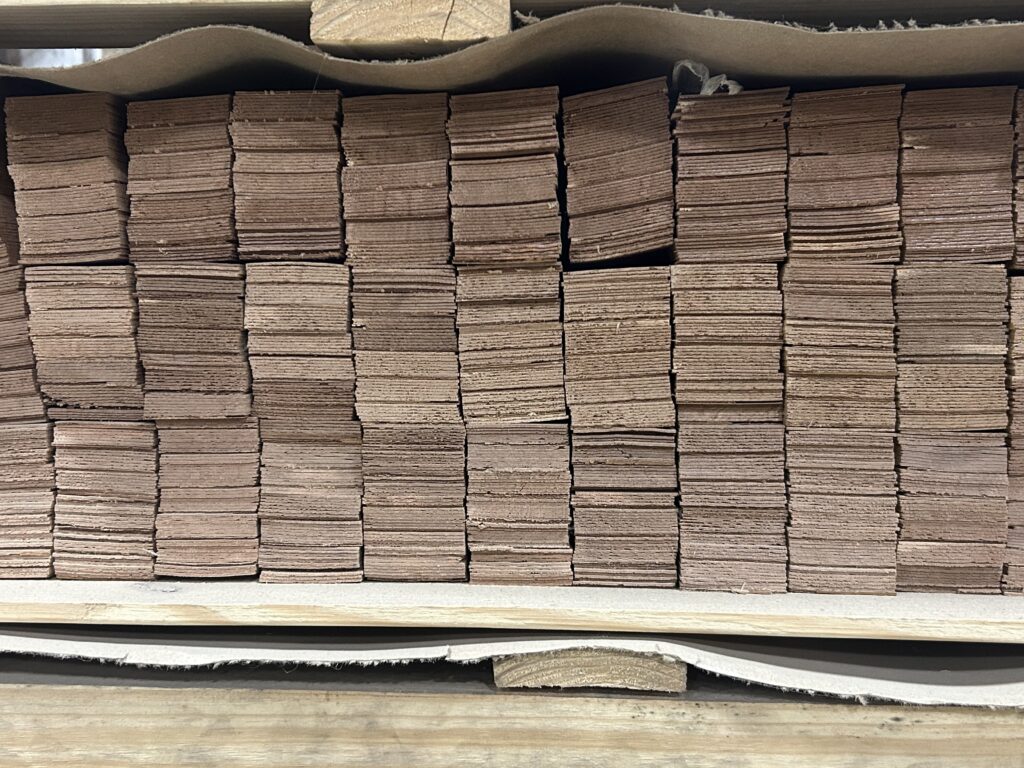

The Freeman Corporation now sits on ~50 acres, with roughly 6 acres (260,000 sq. ft.) under roof. The facility holds four distinct slicer lines, a high-speed rotary veneer line, and multiple specialized clipping, grading, and inspecting lines. The Freeman Corporation ships hardwood veneer all over the world. Major customers include flooring manufacturers, furniture manufacturers, veneer splicing plants, plywood factories, architectural millwork companies, door manufacturers, edge banding manufacturers and veneer resellers.

Through multiple generations as owners and operators in the wood business, we strive to produce the highest quality sliced and rotary veneer in the world. We are wood people at heart and take pride in our work. We appreciate that our products are decorative in nature and are used to create the most beautiful wood products in the industry, helping serve our customers while manufacturing products that are sustainable, long-lasting, and environmentally friendly.

The Tomlinson Company founded by George E. Tomlinson on a 32-acre site in Winchester, KY as a manufacturer of hardwood lumber, tobacco hogsheads, and Tomlinson takedown tables, the first banquet tables that could be instantly disassembled for storage

The Tomlinson Company shifts from a primarily hogshead and table manufacturer to a leading walnut lumber manufacturer

George E. Tomlinson passes away and his grandson, Gene Freeman, takes over the company and begins exporting walnut logs to Italy

First veneer slicer installed as the company is rebranded as The Freeman Corporation, expanding into veneer manufacturing

Gene’s two sons, Reid and George, join the business

High-speed rotary veneer line is added, permanently halting all sawmill operations

Plant adds a fourth veneer slicing line along with 50,000 additional square feet under roof

Installed automatic log watering system to help protect unprocessed logs in log yard during warmer months

Added specialized clipping operation to size veneer to exact customer specifications

Locally owned and American-made

All products are manufactured in the USA at our facility in Winchester, Kentucky

Manufactured with highest quality standards

Generations of experience in wood veneer with meticulous attention to quality

Meticulously graded and inspected

Full-time grading and inspection lines capable of sorting wood into hundreds of grades to best meet customer needs

Environmentally responsible, sustainable, and healthy

Wood is durable, long-lasting, renewable, biodegradable, and proven to be safer and healthier than plastic substitutes