Sliced Veneer

Catalog — Primary Species

The Freeman Corporation slices a variety of hardwood species from across North America. We have highlighted our most frequent species below, but please contact us if you are looking for another species.

Rift, Quartered

Flat

Rift, Quartered, Flat

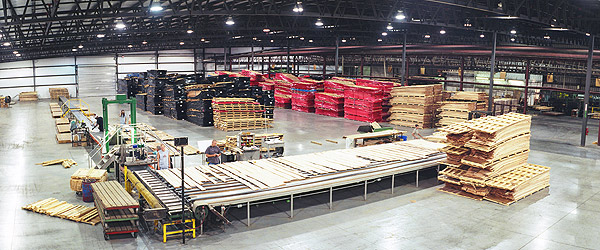

Our Process

Log Procurement

We have a staff of full-time log buyers who are responsible for buying the best hardwoods across North America

Log Yard

We measure and sort every log that arrives at our facility based on species, quality, size, and customer / end market before deciding what veneer product the log is best suited to produce

Flitching

We remove bark from the log with an automated ring debarker and then “flitch” or saw the log into multiple pieces so that the flitches can be sliced into veneer sheets

Vats

We cook the logs in our vats, which are large stainless-steel structures that are programmed to cook the logs for set periods of time to ensure the highest slicing quality. Cook timing varies based on the log species, size, and thickness we plan to produce

Slicing

We have four active veneer slicers – two vertical slicers and two half-round slicers that slice flitched logs into thin veneer sheets. Our slicers are equipped to slice every available veneer species into varying thicknesses based on customer demand

Drying

We have four modern press dryers that are designed to dry the veneer immediately after slicing to help the wood maintain its color and limit any buckling

Clipping

We have multiple clipping lines where we clip veneer sheets to exacting specifications – whether that be based on a customer’s desired grade or size. We can clip to exact dimensions for certain products

Grading / Inspection

We have a full-scale grading and inspection line devoted to sorting wood into groups based on exact specifications. We pride ourselves on having the widest variety of grades, highest attention to detail, and most robust standards in the industry to help customers get the most out of our products

Inquiry

Want to discuss our products? Our team is ready to help.

Locally owned and American-made

All products are manufactured in the USA at our facility in Winchester, Kentucky

Manufactured with highest quality standards

Generations of experience in wood veneer with meticulous attention to quality

Meticulously graded and inspected

Full-time grading and inspection lines capable of sorting wood into hundreds of grades to best meet customer needs

Environmentally responsible, sustainable, and healthy

Wood is durable, long-lasting, renewable, biodegradable, and proven to be safer and healthier than plastic substitutes